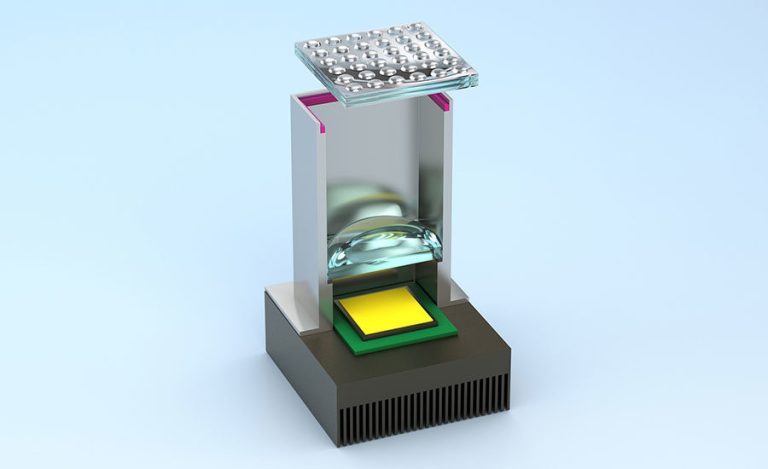

DELO has developed a new adhesive for automotive lighting applications. Photobond OB4189 is resistant to yellowing and has a high aspect ratio, making it particularly suitable for bonding microlens arrays such as headlights and projection systems.

Nowadays, light is considered one of the most important elements of automobile design and differentiation. Microlens arrays play a key role in these developments. Projects LED light with a very short focal length, providing sharp images and discrete shapes. These systems are increasingly being used as optics in headlights and projection systems due to the shallow installation depth required.

To increase efficiency, such microlenses are often made of optically pure polymers. The microlens array is then secured to the housing. Photobond OB4189's high viscosity of 75,000 milliPascals provides high aspect ratios sufficient for bonding processes. Therefore, the adhesive maintains its shape after application and does not flow. This is important for gluing the microlens array. It is also resistant to yellowing, as shown in a life cycle simulation of 500 hours at 140°C.

Modified acrylates are solvent-free and have been developed for use in a temperature range of -40 to 120°C. Compressive shear strength is 30 megapascals (MPa) for polycarbonate and 25 MPa for PMMA. Can be cured with UV light (wavelength 365 nanometers) and visible light (wavelength 400 nanometers). Typical exposure time in visible light for a layer thickness of 100 microns is 5 seconds. This enables a high-precision active alignment process for optical components and reduces cycle times in automated production.

See the company at ASSEMBLY Show South May 1-2 in Nashville, Tennessee.

DELO adhesive

www.delo-adhesives.com