Simulation technology is widely used throughout the automotive industry, from product simulation to ADAS development to crash test scenarios. Engineering simulation company ANSYS has been using simulation technology to turn recycled plastics into functioning auto parts.

It is argued that by using material simulation early in the design process, automotive designers can better evaluate the materials used in their designs, including material variations. This leads to cost and time savings. According to Ansys, this simulation process allows you to simulate a material hundreds of times to understand the performance and variability of your design by simply running the same file repeatedly.

To learn more about this process and what it means for the automotive industry, we spoke with Donna Dykeman, Director of Collaborative Research and Development and Program Manager at Ansys UK Ltd., and Scott Wilkins, Lead Product Marketing Manager at Ansys. I spoke to him.

Just Auto (JA): Can you give us some background about the company?

Donna Dykeman (DD): As a business, we often introduce ourselves as a multi-physics simulation company. Ansys has really grown over the last 50 years in terms of building digitization and coding, the raw physics behind engineering applications. This also applies to the physics of material use.

Ansys covers everything, including mechanical aspects, fluids, and thermal as well as electronics, and has entered many exciting areas such as semiconductors, additive manufacturing, and the list goes on. Everything is based on physics simulation. .

Access the most comprehensive company profiles on the market with GlobalData. Save research time. Increase competitiveness.

Company Profile – Free Sample

You will receive a download email shortly

We are confident in the unique quality of our company profile. However, we want you to make the decision that is most beneficial for your business, so we are offering free samples that you can download by submitting the form below.

by global data

Scott Wilkins (SW): The tagline we use is to drive innovation that drives human progress. I think that represents the essence of this company.

Simulation has become a prerequisite for any engineering business. I think it's due to digitalization. That's the exciting thing when you're in-house and your customers see what they can do and achieve digitally.

That's exactly our area. It's how we can translate the laws of physics into something that can be visualized and achieved digitally. That is our power as a company.

Our customers need it and we need to be able to achieve this for a variety of reasons. They want to bring highly complex products to market as quickly as possible. Simulation is one of the most effective engineering tools, along with CAD, and is starting to gain traction.

It is important to use these techniques very early in the design process. Early involvement can influence the overall future design. This makes the whole process much more efficient.

What is the process of turning recycled plastic into auto parts?

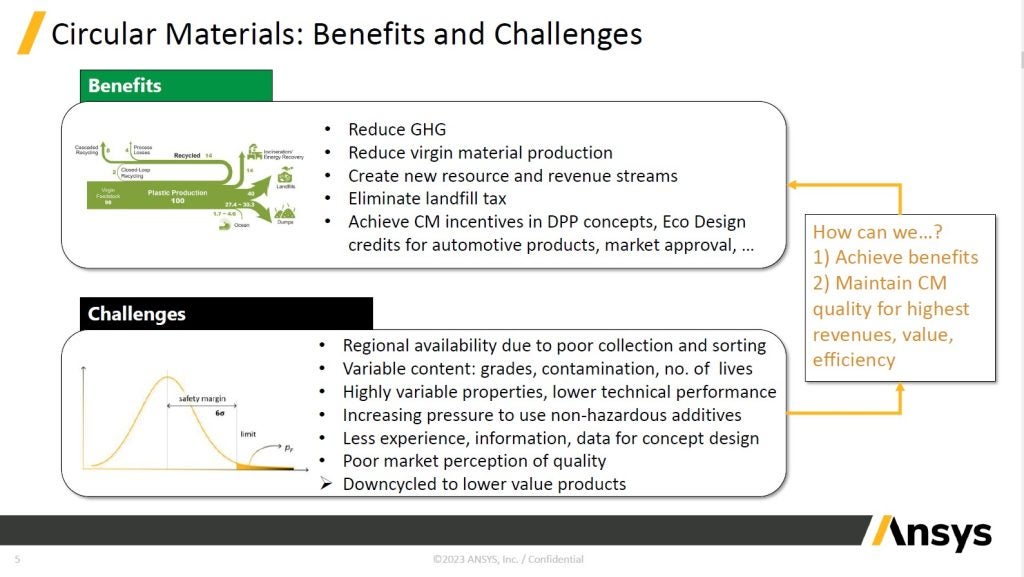

DD: One of the advances in recent years is the ability to generalize and propagate variability in material properties. This is a significant advancement in our software, especially in the physical models we use.

Traditionally, engineers created what are called “deterministic methods.” What this means is that even if you get a single value, you might get another maximum expected value. When you're dealing with randomness in a material, you're looking at the value of that material plus all the parameters, which may have some standard deviation. This is absolutely important when using recycled or highly variable materials in your designs.

Recycled materials present special challenges, especially when extracting materials from municipal waste, something we have worked on in several projects. If there is contamination, there can be multiple grades and even a life cycle where the material has been cut.

Another example of highly variable materials is natural and biomaterials, which are under great pressure when it comes to packaging. All industries in Europe are striving to incorporate a very high proportion of biomaterials into their products and to recycle as much as possible. There's already a very variable material going into it, and you're going to recycle it. Going forward, it will be important to start with material properties and address design variations.

How can simulation technology and materials intelligence help the industry?

SW: We have the ability to adapt the most difficult materials into design applications. If you can understand how it works at the beginning of the design, you can actually start adapting it to different parts of the vehicle. That's the bit that's never really been done before.

In this case, I think we are at the beginning of a journey around the idea that we can use not only recycled plastic, but also by-products. I think using it for car parts is a little different and new.

Most car manufacturers, most OEMs, will choose virgin polymer. Because they know exactly how virgin polymers work and know exactly what to expect from the material. This raises questions for designers early in the lifespan of the vehicle and the parts being considered. Should you use virgin polymers or recycled materials? We can narrow down exactly how recycled materials work and how they work, so we can understand how recycled materials behave, how we can design with them, and what their properties are. You can show what will happen.

DD: It is very beneficial for car companies in terms of reducing risk. Save time and money. As a result, a single representation can be used for many simulations. You have that material card, you have a digital representation of it, and you just use it over and over again.

For example, if you want to manufacture 100 parts from this card, a randomized material card can be simulated 100 times, but traditionally, to get the same representation within the variation, you would have to physically It had to be created and destroyed every time. The time physically saved is a huge benefit.

Are there any examples of it being used?

SW: A very good example is Red Bull Racing. They appeared in the first episode of the television documentary series Driven by Simulation. This episode features one of our Heads of Simulation and talks about how simulation plays a key role in the fluid dynamics around F1 cars. F1 rules change every year, so you need to be able to quickly understand what those small changes mean for your car design. Simulation is a very good way to do that.

So fluid mechanics, the mechanical side of things, different physical properties are all deployed in the simulation along with specialized materials. Materials are the components described within the video.

Our customers are OEM, Tier 1, Tier 2, and across the supply chain. We cover a variety of automotive customers very well, such as Red Bull and Porsche racing. We have a lot of different customers using our technology, and externally we have Lamborghinis and Ferraris using our material management software.

Materials are important inputs to any simulation. You need to understand the material. If you have the right material properties and there is precision behind the material properties, it will lead to accurate simulations. So being able to control what that material is, where it's located, and who's using it across the business becomes very important to people.

What does this mean for the future of the automotive industry?

DD: You know, we've been talking a lot about things like OEM. You know, they're the ones collecting all the parts and putting it together. But in reality, what this type of analysis allows you to do is test the material in a virtual environment and go back to the supplier and say, “No, this is not good enough. We need to reduce the variation by a certain amount, or we need to You'll need to shift the string a little higher to get a better result.”

It is important to be able to test materials and designs in simulation to get the best results. There are many scenarios, iterations, and simulations that can be generated, whether it's CO2 or safety performance such as crash scenarios. To optimize with a recycling supplier and push this down to a competitive overlay with other suppliers, we can say that the variation needs to be reduced by 1.5% standard deviation or the yield strength needs to be increased. . You can then go back and make adjustments. For example, additives can be adjusted or even blended. He might be able to extract one, especially in a grade that is useless in polymers. They can do all kinds of things.

So we're seeing these kinds of workflows that are very iterative, really connecting the supply chain and collaborating in a virtual environment. I think that will be the next important step.

SW: And after three years, the workflow might have been refined and the materials might have been refined. We think the whole concept of being able to use recycled materials will become more prevalent. If car designers knew that they would not have to use virgin polymers in the future and could instead use recycled materials, they would be able to understand its properties and incorporate them into computer models. You can use this as part of your simulation.

With a deeper understanding of the properties of recycled materials, we can imagine vehicle chassis and vehicle components beginning to change. They may be designed with aluminum parts today, but for the past 20 years they have been aluminum parts. Perhaps in the future this will not be the case and it will be recycled materials.

We know we can create it, and design engineers know that we can use it to create it cost-effectively because of this process. We're currently in the process of putting all these tools together into a workflow. This is not easy as it requires a combination of multiple tools. We would understand that and say, “We're going to take this material, run crash tests, optimize it, and use a combination of different simulation tools to create this workflow.'' Some people say, “This is the way to do it.''

In the future, there will be a variety of new materials available for immediate use throughout the supply chain. It will also introduce a new philosophy on how vehicles are designed to incorporate more recycled parts, kickstarting the idea of a true circular economy in car manufacturing.