Enhanced cold spray capabilities allow OEMs to cost-effectively respond to new particulate emissions regulations as they come into effect.Written by Werner Kremer and Paolo Kirchfenning

Air quality in mature economies, especially in large cities, is beginning to benefit from improvements in emissions technology associated with modern sustainable electric propulsion vehicles. However, the vision of a future of emissions-free driving promised by electric vehicles (EVs) is not as completely emissions-free as some believe.

Low environmental impact According to the findings of the BRAke SYStem (LOWBRASYS) project, brake wear can contribute up to 55% (by mass) of non-exhaust traffic-related harmful emissions in dense urban environments. . These emissions consist of carbon-based particulate matter (PM), which originates from fine dust generated during braking. And this is just as true for EVs as it is for internal combustion engine vehicles.

Although vehicle emissions have been significantly reduced in Europe, airborne particulate emissions caused by brakes and tires remain a significant environmental and health issue, especially as the total number of vehicles on the road increases. Masu. Every time your car's brakes are applied, they release small but harmful metal particles produced by brake pad and wheel wear.

According to emissions data from the UK's National Air Emissions Inventory (NAEI), non-exhaust gases (NEEs) are currently estimated to be the main source of both coarse and fine particulate matter from road transport in the UK. I am. Vehicle particles also cause up to 20% of all PM pollution in the atmosphere, with the rest coming from fires, power plants, construction sites, and other industrial activities. The health risks associated with tiny airborne particles have been extensively studied and it has been demonstrated that they can reach the outer regions of the human lungs and therefore pose a serious health hazard. This is especially effective because PM is concentrated in the air near the ground and at the child's height. In addition to physical properties. Brake emissions are typically in the PM10 range in size (10 microns or less in diameter). At this size, it is inhalable and similar in size to pollen, but the particles are smaller (in the PM 2.5 range) and even more easily absorbed.

In its 2022 report on air quality, the European Environment Agency (EEA) states that “96% of urban populations are exposed to levels of fine particulate matter that exceed health-based guideline levels set by the World Health Organization. ” It added: “Exposure to high concentrations of fine particulate matter exceeding 2021 World Health Organization guideline levels resulted in 238,000 premature deaths in the EU27.”

Dust busting with next generation brake coating

The European Parliament has agreed to postpone the tightening of Euro 7 emissions until mid-2030, five years later than planned, but some of the new standards originally proposed for Euro 7 have shifted their focus to non-emissions. There is no doubt that it is. A widely cited study by Emissions Analytics, an independent emissions testing company, found that as a vehicle's mass and propulsion torque increase, particulate matter emissions also increase. And the average EV has a half-ton battery, so it is inevitable that EV manufacturers will be affected, despite recent delays in tightening regulations.

Ceramic brake pads generally produce less brake dust than metal brake pads (and the dust they produce is less toxic), but they do not work efficiently until warmed up, making them less suitable for the average consumer. is not a viable solution for cars. And with optimal functionality. As a result, its use is mainly limited to racing vehicles and some high-end luxury and performance cars.

An additional challenge is that EVs' regenerative braking systems typically mean brake usage is not as intense as in combustion vehicles. This reduced usage can make metal brakes more susceptible to corrosion, which can affect functionality and safety, resulting in the need for frequent disc replacements or replacement of the entire brake system. . The best solution so far is to coat the brake discs with a combination of metal alloys and ceramic powders. This is a combination of highly corrosion-resistant materials, resulting in a coating that provides little or no resistance.

EV heat sink thermal management

As EVs become more powerful and include larger batteries, they require more powerful systems for better cooling. The most advanced automotive heat sinks (essentially heat exchangers that help transfer heat from the engine to the outside environment) are now commonly hybrid models made of copper and aluminum. Traditionally, these were made from pure copper or pure aluminum, but faced weight or manufacturing issues. Copper can be soldered, but it is heavier and will reduce mileage. For every 10 km, the vehicle travels 1 km less. Similarly, although aluminum is lightweight, it cannot be soldered, creating challenges for efficient manufacturing.

By spraying a 100-200 micron copper coating onto an aluminum substrate, heatsink manufacturers can harness the benefits of both materials and achieve 30% better performance than aluminum alone. Copper has significantly better thermal conductivity, and the ability to solder components can increase heat transfer by an additional 20%. The use of copper coatings also helps avoid hot spots that can reduce vehicle efficiency, reduce range, and shorten vehicle life due to overheating. And mainly aluminum-based parts can still increase range.

While cold spraying heat sinks has been a common application for the past few decades, spraying copper coatings on aluminum is relatively new. The automotive industry currently requires highly efficient, effective, and inexpensive solutions.

Next generation cold spray for next generation cars

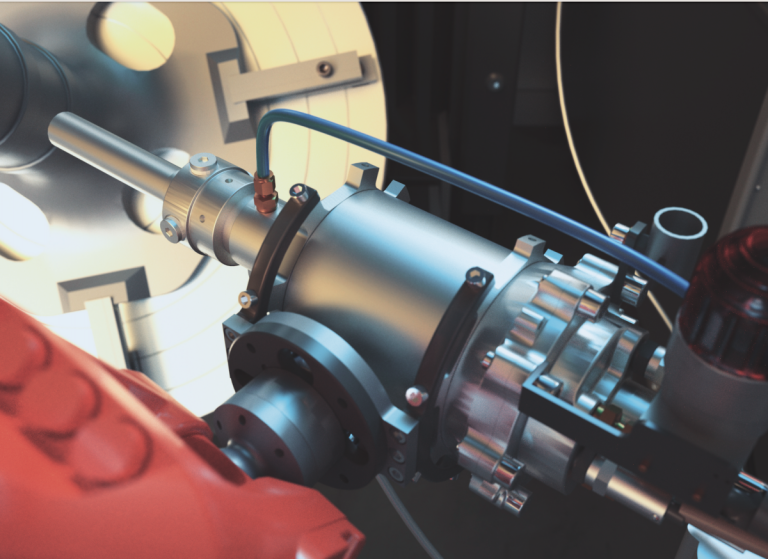

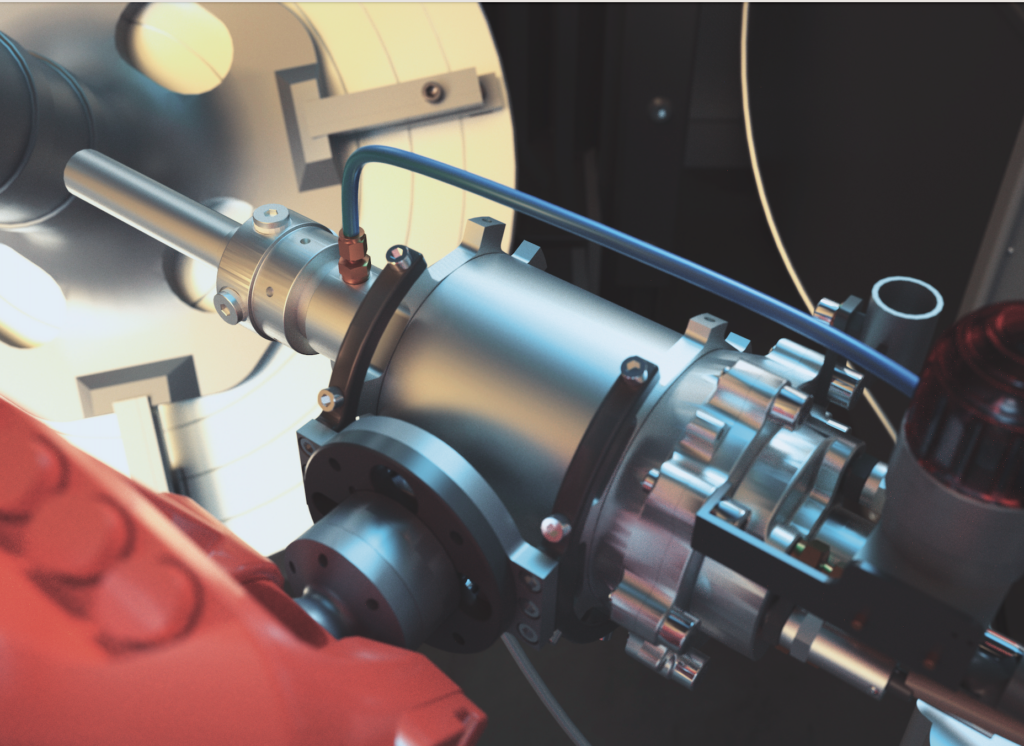

Cold spraying is a material deposition technique that uses high-pressure gas to spray tiny metal particles, 5 to 50 microns, onto a substrate (in this case, a brake). Particles that begin their lives at ambient temperature are placed in a nitrogen or helium gas stream, then heated and accelerated through a supersonic nozzle at incredible speeds of 500 to 1200 meters per second. During the process, the temperature of the metal powder is kept well below its melting point, ensuring that the metal particles remain in the solid phase, preserving their unique properties and maintaining their oxidation resistance. The coatings created by this process are ductile, which also prevents the risk of embrittlement under stress.

Due to the high temperatures (up to 1,100 °C) required in the gas stream, the production of coated products requires many challenges, including the supply of high-purity gas and a stable and reliable gas flow with minimal pressure fluctuations. depends largely on factors. —Everything must be within the specified temperature range. Sudden temperature changes can damage both the gas heater and the nozzle at the tip of the spray gun. Stable and reliable pressure is required to ensure smooth gas flow, which ultimately affects the quality of the coating. Variations can affect the ability to achieve a uniform coating and ultimately have a negative impact on the overall product quality.

This is where the Linspray Connect system comes into play. Developed by Linde in collaboration with German cold spray technology company Impact Innovations, his Linspray is designed to ensure a reliable, consistent, high-quality gas flow with minimal fluctuations. This innovative system allows car manufacturers to monitor process parameters such as pressure, temperature and nitrogen tank fill level. It also has the ability to automatically send error messages in real time, allowing you to switch to emergency gas supply or safely shut down the system in the event of an accident. You can also easily increase or decrease production as needed.

These enhanced features not only allow automakers to cost-effectively respond to new particulate emissions regulations when they come into effect, but also improve brake corrosion resistance, giving OEMs a competitive advantage. can bring. For EV drivers, this means they can be confident that their choice of electric vehicle not only benefits from increased range and reduced maintenance, but also makes a real contribution to reducing air pollution.

About the author: Werner Krömmer oversees business development for the manufacturing industry. Linde Technologies. Paolo Kirchfenning is Global Commercialization Manager at Linde Technologies